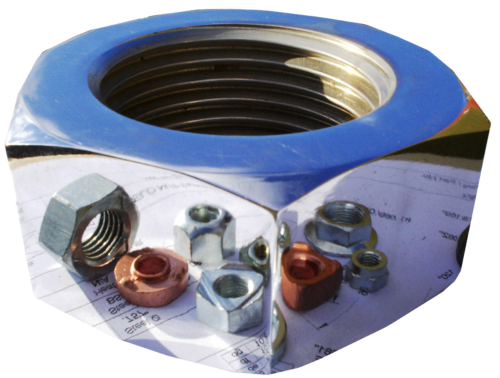

Nuts And Parts We Stock And Custom Manufacture

Serving industries with

cold and hot forged

nuts and bespoke parts

We manufacture and stock a wide range of Cold Forged parts from M5 to M16 diameter. We can also source fully certified, quality Hot Forged parts from M20 to M64 diameter from our trusted partners. Our substantial factory and warehouse in Corby, Northants, serves clients across the UK and Europe, typically in the following sectors.

AMC – British manufacturing at its best

At AMC, our products embody the reliable and efficient qualities associated with British manufacturing. Every nut, fastener and bespoke part we create is a product of our steadfast commitment to superior craftsmanship and high operational standards. Being British-made is not just about origin - it signifies the consistent quality, durability, and excellence inherent in our production processes. When you choose AMC, a proud member of the Confederation of British Metalforming, you're investing in reliable, top-grade fasteners and nuts that perform exceptionally in all conditions. That's the real-world, functional advantage of choosing our British-made goods - solid, dependable, and built to deliver.

Your trusted source of quality and excellence in nuts and fasteners

We understand that in your business, quality is not just a preference, it's a necessity. That's why at AMC, quality isn't just a part of our process, it's our ethos. It’s exemplified by our ISO9001 Quality Management System so you have peace of mind knowing your supplies are being manufactured to the highest possible standards.

ISIR Certification

Initial Sample Inspection Report.

In House Inspection & Testing

Testing & Inspection Facilities including Proof Load & Hardness Testing.

3.1 Certification EN10204:2004 3.1

Certification for Raw Material & Mechanical properties.

PPAP

Level 5

PPAP Documention to Levels 1-5

AMC’s machine capabilities

Size Range: M4 - M16

Capacity: 40 Million Parts per annum

Forging Capabilities

One 3/8” National Progression Cold Nut Forging Machine.

Two 5/16” National Progression Cold Nut Forging Machines.

Three 5/16” National Progression Cold Nut Forging Machines.

One 5/8” National Progression Cold Nut Forging Machines.

Tapping Capabilities

One Nutap Mas14F Auto Tapping Machine.

Four Nutap Mas 20 Auto Tapping Machines.

Eight Mas 14 Auto Tapping Machines.

One Hydraulic Distortion Press.

One Avery Proof Load Testing Machine (Maximum Proof Load Testing Capability 50 Tonnes).

Bringing solutions to engineering challenges through innovation

Our UK-based manufacturing team has honed their experience and knowledge to swiftly respond to unique customer requirements. We design for manufacture and thrive on creating custom solutions for extraordinary needs, partnering with our clients to optimise costs and processes. Our responsive manufacturing processes are designed to handle smaller batch production runs, ensuring we're always ready to cater to your changing demands.

Why clients choose AMC:

Exceptional people generating extraordinary solutions

But it's not just our process that sets us apart, it's our people. Our skilled and experienced workforce forms the backbone of AMC. We have a solution-focused innovative manufacturing operations team who will work closely with you and your designs to find a solution to the most complex of challenges with bespoke parts you can rely on.

![IMG_E4416[1] IMG_E4416[1]](wp-content/uploads/2023/09/IMG_E44161-scaled.jpg)

Simplify your engineering challenges with AMC today

Step 1 - Share Your Vision:

No matter how complex or unique, our solution-oriented team is ready to work with your designs to find a bespoke solution tailored to your specifications.

Step 2 - Review & Collaborate:

We believe in teamwork. We work with our customers' design to assist with or achieve design for manufacture, ensuring quality and cost efficiencies. Your success is our mission, and your satisfaction our highest reward.

Step 3 - From Concept to Reality:

With the plan approved, your bespoke parts move to production, under the watchful eyes of our seasoned team and stringent quality controls. Trust AMC's efficient processes to ensure timely delivery, allowing you to focus on what you do best: ensuring the efficient manufacture of your products.

Can you afford to choose the wrong supplier?

You shouldn’t have to worry about quality, traceability or timely delivery when choosing your supplier. When you choose AMC, you can rest assured you’re selecting a partner dedicated to solving your challenges and ensuring your success. Our commitment to zero-defect production, responsive service and innovative solutions ensures you’re investing in reliability, efficiency and excellence. Contact our team today.

COLD FORGED NUTS AND FASTENERS

FREQUENTLY ASKED QUESTIONS

Using sub-standard quality nuts and fasteners can pose significant risks, including structural failures, safety hazards, increased maintenance costs, and operational downtime, ultimately impacting the reliability and safety of equipment or structures.